Lockheed Martin has completed the Block 8.1.1 upgrade for the Royal Australian Air Force's (RAAF)…

Saab reveals world’s first software-defined aircraft fuselage with Divergent Technologies

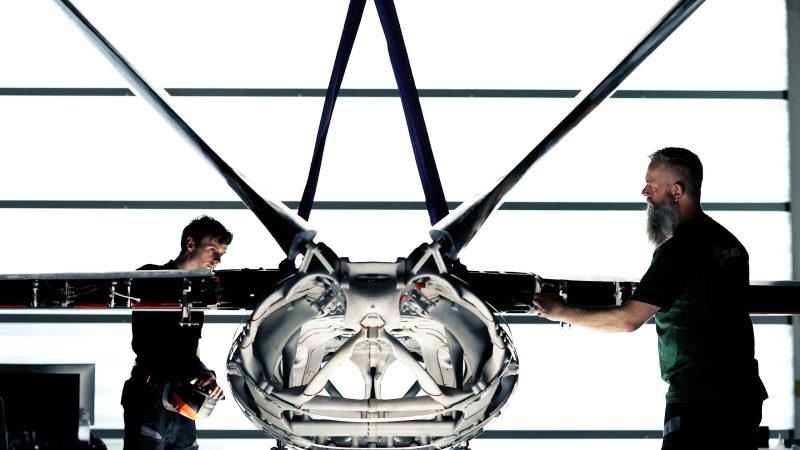

Swedish defence manufacturer Saab has worked with Los Angeles-based Divergent Technologies to design and manufacture what Saab describes as the world’s first software-defined aircraft fuselage. The 3D-printed Ruby is an Uncrewed Aerial System with a 5-7m wingspan and is powered by a General Electric J85 turbojet engine.

Saab has worked with Divergent Technologies to design and manufacture the Ruby. Its fuselage was developed and realized with no unique tooling or fixtures. Instead, it was developed using Divergent’s software-defined manufacturing assets that combine industrial-rate laser powder fusion Additive Manufacturing (AM) with universal robotic assembly.

“The fuselage has successfully passed its structural proof-loading and is scheduled to fly in 2026,” says Axel Bååthe, Head of Saab R&D centre, The Rainforest.

The fuselage, at over 5 metres long and comprising of 26 unique printed parts, will be one of the largest additively manufactured metal structures that will have ever undergone powered flight, said Saab.

“We are asking ourselves the question – in Gripen E (the JAS39 fighter), customers get a platform where they can code mission-critical (software) applications in the morning and fly them in the afternoon. How can we give them the same level of software flexibility, but for actual hardware? We call this Software-Defined Hardware Manufacturing,” said Bååthe.

“Many traditional truths in aircraft manufacturing were possible to challenge by the joint Saab and Divergent design team,” says Bååthe. “With AM load-bearing structures do not have to follow straight lines and right angles like ribs and stringers, but can rather, organically, follow the optimal load-paths. It is impossible to, as a human, draw these parts, instead they must be generated by optimization and AI-algorithms.”

This innovative approach to industrial hardware manufacturing makes it possible to rapidly produce, test, and iterate physical structures at speeds comparable to those of software engineering workflows, says Saab. The lead time from design to finished product is no longer dictated by expensive investments in new tooling but is instead determined by the speed of design algorithms and print or robot time, Bååthe explains. This approach also reduces the cost of change, making redesign and implementing innovative ideas easier.

“The joint team has done an excellent job working to prepare for first flight and in paving the way forward as we advance towards our ambition of ‘CAD in the Morning, Fly in the Afternoon’,” adds Bååthe.

With this technology, the number of parts in a fuselage can be reduced by at least a factor of 100, replacing traditional riveted machine parts with organic, interwoven structures. This leads to dramatically lower lead times in assembly. This technology also enables more flexible weight optimization and functional integration within fuselage structures, allowing for the printing of wiring, thermal management systems, and hydraulic and liquid systems directly inside the structure, further improving performance.